Finstral’s recycling journey

Finstral is setting new benchmarks in recycling and carbon reduction.

The company is single-mindedly pursuing the goal of reducing the ecological footprint of its products and closing material cycles. With a string of innovative measures, the company is underlining its pioneering role in sustainability.

Carbon-reduced uPVC granulate

Since 2025, Finstral has been exclusively using uPVC granulate, which is entirely produced using green electricity. In production alone, carbon emissions per kilogram have reduced by around 25%. “uPVC is easy to recycle – if the quality is right,” explains Matthias Fauster, Head of Production at the profile extrusion plant. “We stopped using lead as an additive in 2004, long before the EU-wide ban in 2015. This ban was temporarily eased for recycled materials. And yet our profiles remain lead-free – and thus completely recyclable.”

Old windows, new circuit.

To truly understand processes, you need to control them yourself. And that’s why Finstral is starting its own recycling project for old windows at its Oppeano site. The goal is to gain a detailed understanding of the entire return and recycling process in all its phases – including permits, regulatory requirements, the wide variety of material formulants and potential contaminants, separation into pure materials, and the organisation of a functioning logistics network. This will result in first-hand experience – on the challenges of the product lifecycle and what is takes to make old materials usable again. As Florian Oberrauch, member of the Finstral Board of Directors, points out: “Sustainability begins with the details. Finstral is aiming to reduce its carbon footprint – not just through certificates, but by measurably reducing its actual environmental impact.” For Oberrauch, this means “saving energy and using renewable sources wherever possible – ideally self-generated. Avoiding production waste, from offcuts to sawdust. Configuring production to allow recycling of pure materials. And working with our suppliers to close any gaps in the material circuit. This presents technical, legal and economic challenges – but this is the path we have chosen. And it is a path we are taking earlier than many others.”

Carbon-reduced uPVC granulate

Since 2025, Finstral has been exclusively using uPVC granulate, which is entirely produced using green electricity. In production alone, carbon emissions per kilogram have reduced by around 25%. “uPVC is easy to recycle – if the quality is right,” explains Matthias Fauster, Head of Production at the profile extrusion plant. “We stopped using lead as an additive in 2004, long before the EU-wide ban in 2015. This ban was temporarily eased for recycled materials. And yet our profiles remain lead-free – and thus completely recyclable.”

Old windows, new circuit.

To truly understand processes, you need to control them yourself. And that’s why Finstral is starting its own recycling project for old windows at its Oppeano site. The goal is to gain a detailed understanding of the entire return and recycling process in all its phases – including permits, regulatory requirements, the wide variety of material formulants and potential contaminants, separation into pure materials, and the organisation of a functioning logistics network. This will result in first-hand experience – on the challenges of the product lifecycle and what is takes to make old materials usable again. As Florian Oberrauch, member of the Finstral Board of Directors, points out: “Sustainability begins with the details. Finstral is aiming to reduce its carbon footprint – not just through certificates, but by measurably reducing its actual environmental impact.” For Oberrauch, this means “saving energy and using renewable sources wherever possible – ideally self-generated. Avoiding production waste, from offcuts to sawdust. Configuring production to allow recycling of pure materials. And working with our suppliers to close any gaps in the material circuit. This presents technical, legal and economic challenges – but this is the path we have chosen. And it is a path we are taking earlier than many others.”

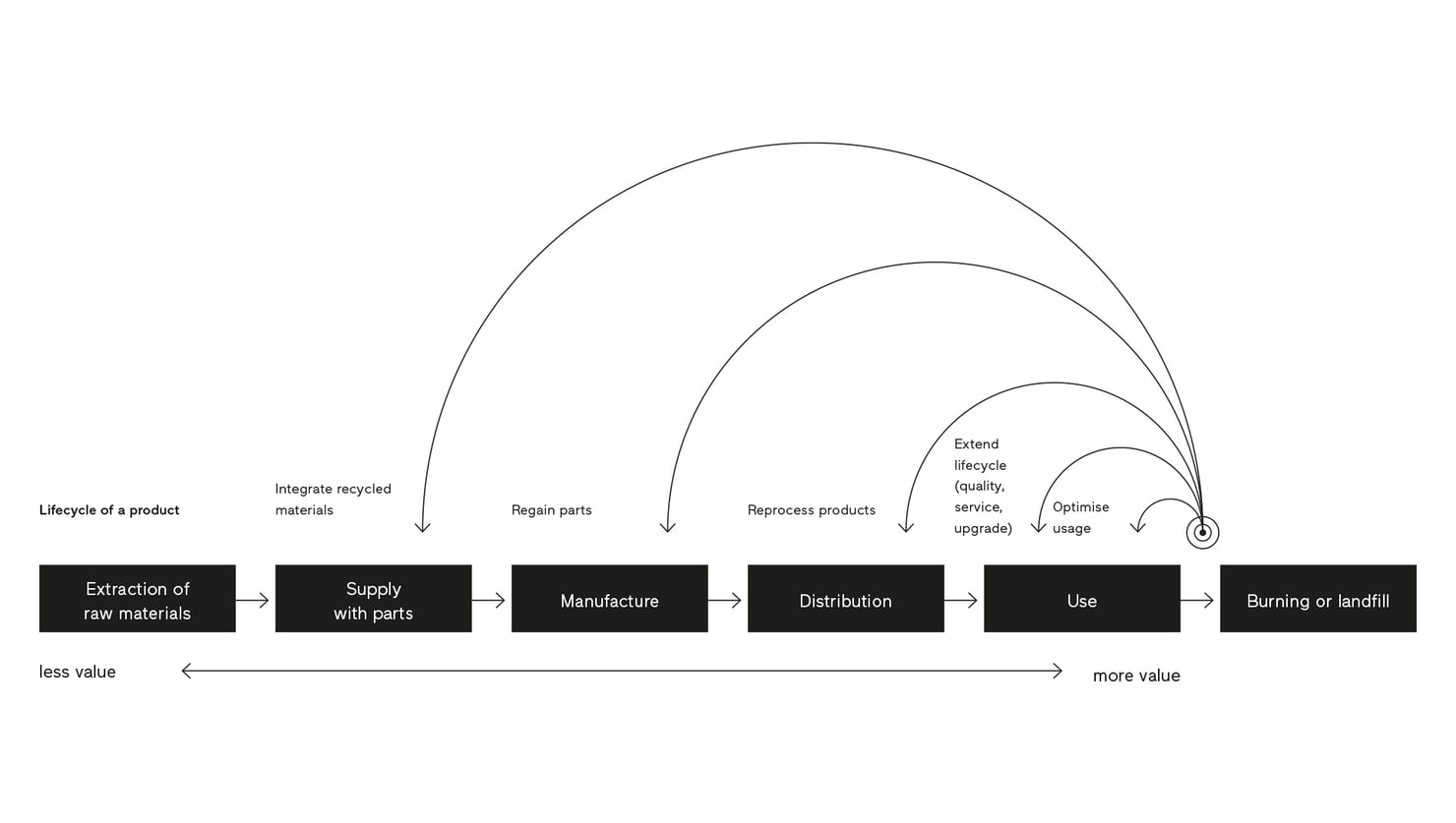

There’s recycling – and then there’s recycling.

The goal: less downcycling, longer lifecycle, more circularity.

There are many ways to reduce the carbon footprint of your own products. Finstral regularly reviews which of the “R strategies” it can reasonably apply – recover, recycle, repurpose, refurbish, repair, reuse, reduce, rethink and refuse. Each measure helps improve processes and products.

The goal: less downcycling, longer lifecycle, more circularity.

There are many ways to reduce the carbon footprint of your own products. Finstral regularly reviews which of the “R strategies” it can reasonably apply – recover, recycle, repurpose, refurbish, repair, reuse, reduce, rethink and refuse. Each measure helps improve processes and products.

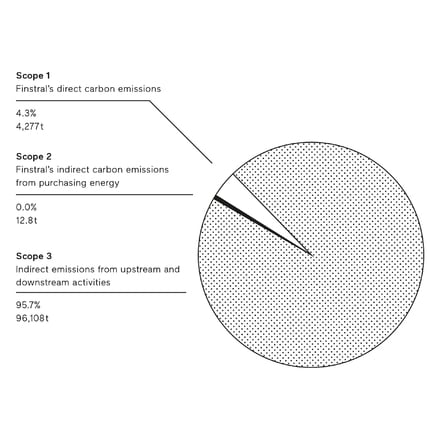

The materials are the largest carbon sources.

Finstral will be carbon-neutral in Scope 1 and 2 by 2030. By 2024, carbon emissions in these two areas had already fallen by 69% compared to the reference year 2012. But the majority of the carbon footprint associated with our activities comes from the materials we use in our products. Therefore, our focus in future will be on improving recycling opportunities and closing any gaps in material circuits.

Finstral will be carbon-neutral in Scope 1 and 2 by 2030. By 2024, carbon emissions in these two areas had already fallen by 69% compared to the reference year 2012. But the majority of the carbon footprint associated with our activities comes from the materials we use in our products. Therefore, our focus in future will be on improving recycling opportunities and closing any gaps in material circuits.

58 % secondary aluminium.

In 2024, the proportion of secondary aluminium was 58% of the overall volume processed. To remain flexible in the face of market changes, Finstral elects not to use raw anodised aluminium. Instead, it uses aluminium with a powder coat in a comparable colour. The reason: compared to primary aluminium, secondary aluminium produces around 90% less CO2 (0.5 kg as opposed to 10 kg CO2/kg), but cannot be anodised without optical flaws as the surface becomes flaky. “Aluminium is light, pliable, stable and infinitely recyclable,” explains Günther Zipperle, who is in charge of the company’s aluminium powder-coating operations. “Long-lasting powder coating can even lend new life to used profiles. This ensures the material remains high quality, elegant and future-proof.”

6.64 kg: CO2 equivalent per square metre in carbon-reduced float glass.

Starting in 2025, Finstral is gradually introducing float glass with a reduced carbon footprint: 6.64 kg CO2 equivalent per square metre – calculated “from cradle to grave” for a glass thickness of 4 mm. This comes from the higher proportion of recycled façade glass, which reduces emissions by 42% compared to conventional float glass – without sacrificing technical or aesthetic properties. “Even after extensive recycling, glass retains its quality and its appearance,” says Massimo Rova, who heads up Finstral’s insulation glass plant at Oppeano. “My hope is that in 20 to 25 years, almost every company in this field will achieve a complete circular economy.”

3.5 years ...

… is the time it takes for new windows to offset the carbon emissions required for their materials, manufacturing and installation through the reduction of the building’s energy requirements. As environmental engineer Katrien Romagnoli explains, the focus of efforts varies according to the material: “There are different sustainability priorities for each material. For aluminium, recycling is important, for glass it’s the production process, and for uPVC it’s a balance of high recycling rates and lead-free processing. It’s important to see the wider context.”

These results were calculated using a lifecycle analysis model developed by Fraunhofer Italia Research on behalf of Finstral. The basis was the Passive House Project Package (PHPP) and Finstral’s externally verified environmental product declarations (EPDs). This was based on a comparison of the average Finstral window sold in 2024 with an old wooden window (Uf 2.2 W/m²K) with double glazing (Ug 2.9 W/m²K, g-value 0.75). The calculation related to a reference house with gas heating and climate data for Bolzano, South Tyrol.

In 2024, the proportion of secondary aluminium was 58% of the overall volume processed. To remain flexible in the face of market changes, Finstral elects not to use raw anodised aluminium. Instead, it uses aluminium with a powder coat in a comparable colour. The reason: compared to primary aluminium, secondary aluminium produces around 90% less CO2 (0.5 kg as opposed to 10 kg CO2/kg), but cannot be anodised without optical flaws as the surface becomes flaky. “Aluminium is light, pliable, stable and infinitely recyclable,” explains Günther Zipperle, who is in charge of the company’s aluminium powder-coating operations. “Long-lasting powder coating can even lend new life to used profiles. This ensures the material remains high quality, elegant and future-proof.”

6.64 kg: CO2 equivalent per square metre in carbon-reduced float glass.

Starting in 2025, Finstral is gradually introducing float glass with a reduced carbon footprint: 6.64 kg CO2 equivalent per square metre – calculated “from cradle to grave” for a glass thickness of 4 mm. This comes from the higher proportion of recycled façade glass, which reduces emissions by 42% compared to conventional float glass – without sacrificing technical or aesthetic properties. “Even after extensive recycling, glass retains its quality and its appearance,” says Massimo Rova, who heads up Finstral’s insulation glass plant at Oppeano. “My hope is that in 20 to 25 years, almost every company in this field will achieve a complete circular economy.”

3.5 years ...

… is the time it takes for new windows to offset the carbon emissions required for their materials, manufacturing and installation through the reduction of the building’s energy requirements. As environmental engineer Katrien Romagnoli explains, the focus of efforts varies according to the material: “There are different sustainability priorities for each material. For aluminium, recycling is important, for glass it’s the production process, and for uPVC it’s a balance of high recycling rates and lead-free processing. It’s important to see the wider context.”

These results were calculated using a lifecycle analysis model developed by Fraunhofer Italia Research on behalf of Finstral. The basis was the Passive House Project Package (PHPP) and Finstral’s externally verified environmental product declarations (EPDs). This was based on a comparison of the average Finstral window sold in 2024 with an old wooden window (Uf 2.2 W/m²K) with double glazing (Ug 2.9 W/m²K, g-value 0.75). The calculation related to a reference house with gas heating and climate data for Bolzano, South Tyrol.

Florian Oberrauch is responsible for production and logistics on the Finstral Executive Board and Vice-President of the Board of Directors. He established direct sales for large-scale projects in the contract business and is increasingly taking on sales responsibility from his father Luis Oberrauch.

Katrien Romagnoli, MSc, environmental engineer, who is analysing Finstral’s environmental impact on an ongoing basis. Her focus includes conservation, purchase and generation of energy, zero-waste production, internal establishment of environmental product declarations (finstral.com/epd) and corporate sustainability reporting (CSR).

Massimo Rova, qualified electronic and industrial technician with extensive experience in the electrical engineering, stove and metal construction industries. Massimo Rova heads up the Finstral insulation glassworks in Oppeano.

Matthias Fauster is a qualified mechatronics engineer and has been working for Finstral for 13 years. After seven years in quality control, he was responsible for plant management for three years before he was named Head of Production of the profile extrusion works three years ago.

Günther Zipperle has been at Finstral since 2012. He started out in the time management field and since 2019 he has been heading up production of aluminium powder coating and the central store and cutting facility in Borgo

Still want more?

See here for further interesting reading matter.