Reframe Production.

Quality loves quantity.

Quality isn’t an absolute value, it’s a matter of definition. That’s why we have requirements, standards and guidelines for all sorts of things – including windows and doors. At Finstral, we see standards as minimum requirements. Our own standards for functionality, aesthetics, comfort and durability go much further. Perhaps because we started off as a workshop and we remain a family company to this day. Of course, production has changed considerably since the company was established in 1969; it’s become more efficient, more thoughtful in its use of materials and energy. But one thing has remained the same throughout the years: we make (almost) everything ourselves. This means we can set our own standards – from the conception and profile extrusion to the installation. And it is this principle that makes us what we are: one of Europe’s leading window manufacturers. But all artisanal romanticism aside, our guiding principle for window production is: volume ensures perfection. For greater quality, you need greater quantity.

Text: Stefan Sippell

Photos: Mattia Balsamini

Robot

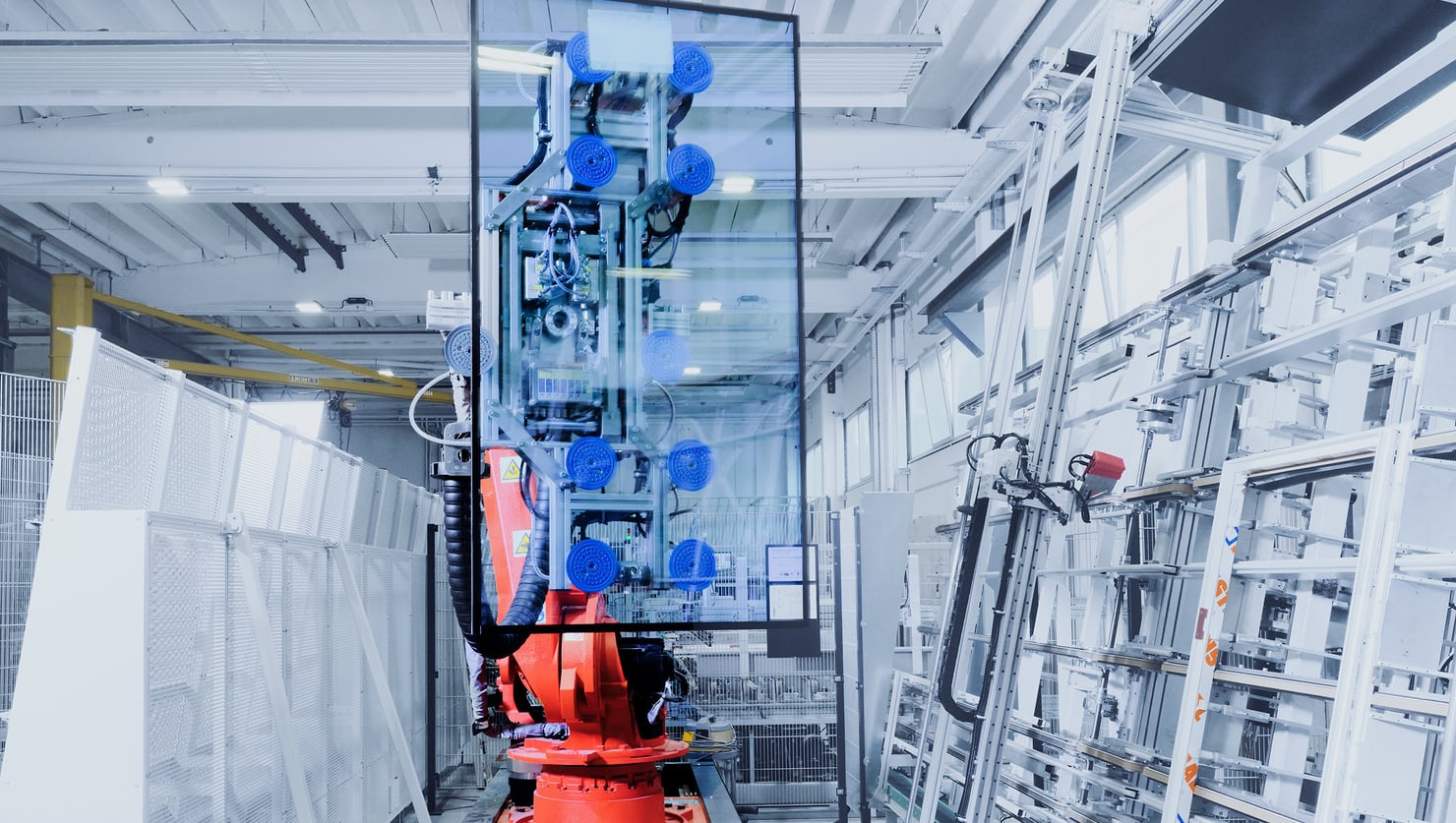

A new robot in the Finstral window production facility in Oppeano (Italy) sets the insulation glazing in window frames – and while it isn’t faster than a human worker, it is more precise, persistent and reliable. This saves workers from having to haul around heavy glass panes and ensures consistent quality. And this quality would be impossible without quantity, because it is the high utilisation rate at the facility that enables investment in the machines and in the programming, management and maintenance they require.

High-bay warehouse

Quantity: Known to employees as the “supermarket”, the central storeroom in Kurtatsch, South Tyrol, serves as the materials hub for all 14 Finstral plants. Two high-bay shelf units (70 and 100 metres long respectively, 10 metres high, photo left) hold 4,306 containers at all times, with another 2,000 in the courtyard and 6,000 in or circulating between the plants. In the containers are uPVC profiles. In Kurtatsch there are always 3,000 tonnes of profiles on hand, measuring 3,600 kilometres in total; each year 10,000 tonnes (11,300 kilometres) are deployed.

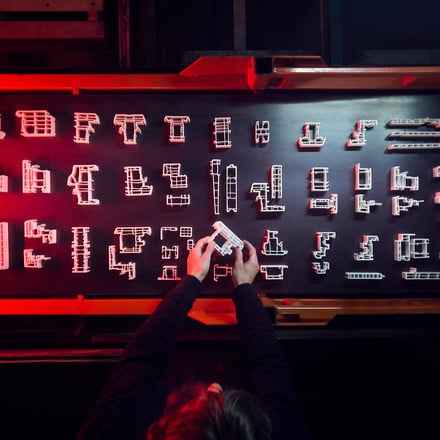

Quality: Finstral offers 230 different profile geometries (photo above, selection). This figure includes seven sash designs, countless frame versions and installation profiles for just about every European building connection, with colour and surface options on top of that. It is this warehouse that makes the enormous range manageable; centralisation and automation ensure that each profile is available at the right production site at the right time. In other words, it is the organisation of mass that enables the handling of the individual item.

Mixer

Quality: Finstral has been making uPVC profiles here, rather than buying them in, for over 45 years. They are made of uPVC granulate, which now includes 23% recycled materials. The consistently top-quality formula boasts high resistance to impact and UV light, which ensures durability – in excess of the standards set by quality seals (RAL, CSTB). High-quality pigments are mixed with the granulate to produce uPVC in around a dozen colours (photo left; here in a brown shade) instead of the usual practice of coating white profiles with film. The consistent colouring ensures a uniform appearance, even when the sash is open.

Quantity: Finstral processes over eight million kilograms of granulate each year. This large volume allows for the use of ultra-modern, energy-saving mixing facilities in the South Tyrol extrusion works (photo above). They ensure that dosages of all the pigments and additives are exact down to the decimal point, precisely control the temperature in the heating/cooling mixer and guide the mixture to extrusion – completely automatically, for optimal quality consistency.

Text: Stefan Sippell

Photos: Mattia Balsamini

Robot

A new robot in the Finstral window production facility in Oppeano (Italy) sets the insulation glazing in window frames – and while it isn’t faster than a human worker, it is more precise, persistent and reliable. This saves workers from having to haul around heavy glass panes and ensures consistent quality. And this quality would be impossible without quantity, because it is the high utilisation rate at the facility that enables investment in the machines and in the programming, management and maintenance they require.

High-bay warehouse

Quantity: Known to employees as the “supermarket”, the central storeroom in Kurtatsch, South Tyrol, serves as the materials hub for all 14 Finstral plants. Two high-bay shelf units (70 and 100 metres long respectively, 10 metres high, photo left) hold 4,306 containers at all times, with another 2,000 in the courtyard and 6,000 in or circulating between the plants. In the containers are uPVC profiles. In Kurtatsch there are always 3,000 tonnes of profiles on hand, measuring 3,600 kilometres in total; each year 10,000 tonnes (11,300 kilometres) are deployed.

Quality: Finstral offers 230 different profile geometries (photo above, selection). This figure includes seven sash designs, countless frame versions and installation profiles for just about every European building connection, with colour and surface options on top of that. It is this warehouse that makes the enormous range manageable; centralisation and automation ensure that each profile is available at the right production site at the right time. In other words, it is the organisation of mass that enables the handling of the individual item.

Mixer

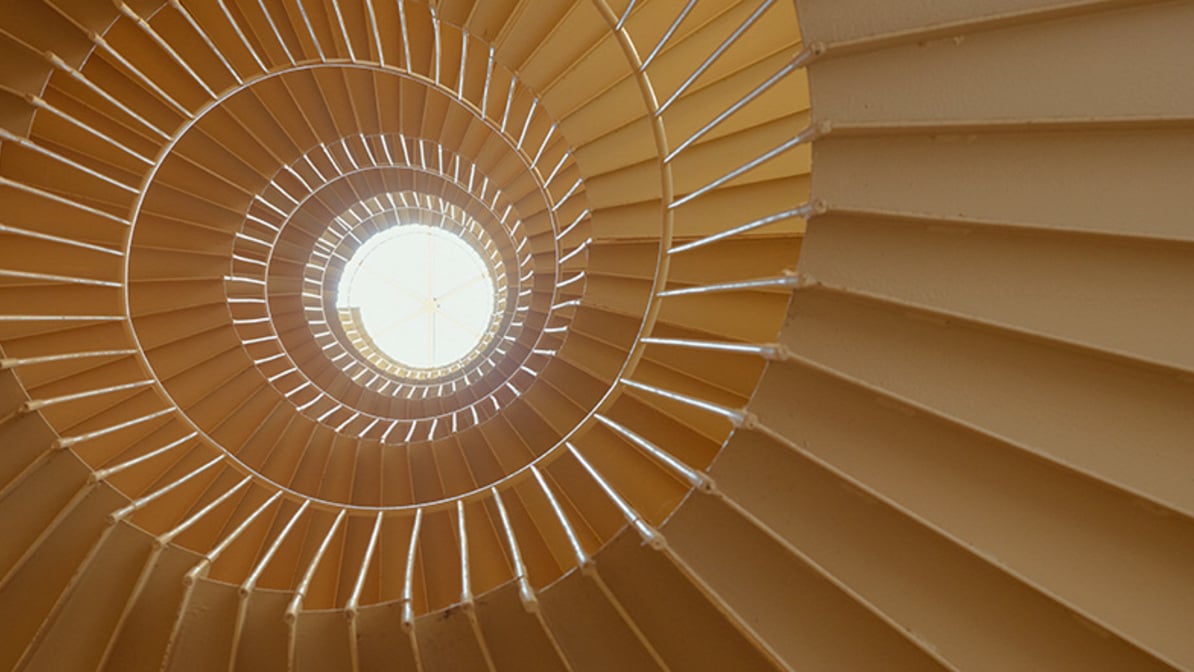

Quality: Finstral has been making uPVC profiles here, rather than buying them in, for over 45 years. They are made of uPVC granulate, which now includes 23% recycled materials. The consistently top-quality formula boasts high resistance to impact and UV light, which ensures durability – in excess of the standards set by quality seals (RAL, CSTB). High-quality pigments are mixed with the granulate to produce uPVC in around a dozen colours (photo left; here in a brown shade) instead of the usual practice of coating white profiles with film. The consistent colouring ensures a uniform appearance, even when the sash is open.

Quantity: Finstral processes over eight million kilograms of granulate each year. This large volume allows for the use of ultra-modern, energy-saving mixing facilities in the South Tyrol extrusion works (photo above). They ensure that dosages of all the pigments and additives are exact down to the decimal point, precisely control the temperature in the heating/cooling mixer and guide the mixture to extrusion – completely automatically, for optimal quality consistency.

Robot

High-bay warehouse

High-bay warehouse

Mixer

Mixer

Aluminium powder coating

Quantity: Since 2019, Finstral has had a powder coating facility for aluminium facings in Borgo Valsugana (Trentino). Around 10,000 rods are processed here every week, delivered from the warehouse in 450 geometric variants – as raw aluminium with at least 50 percent recycled materials. A computer optimises the placement of the hangers and the sequence of process steps, depending on the colour. In total, the Finstral portfolio includes 260 colour variants; 80 to 120 of them are produced in any given week (photo above, here in white).

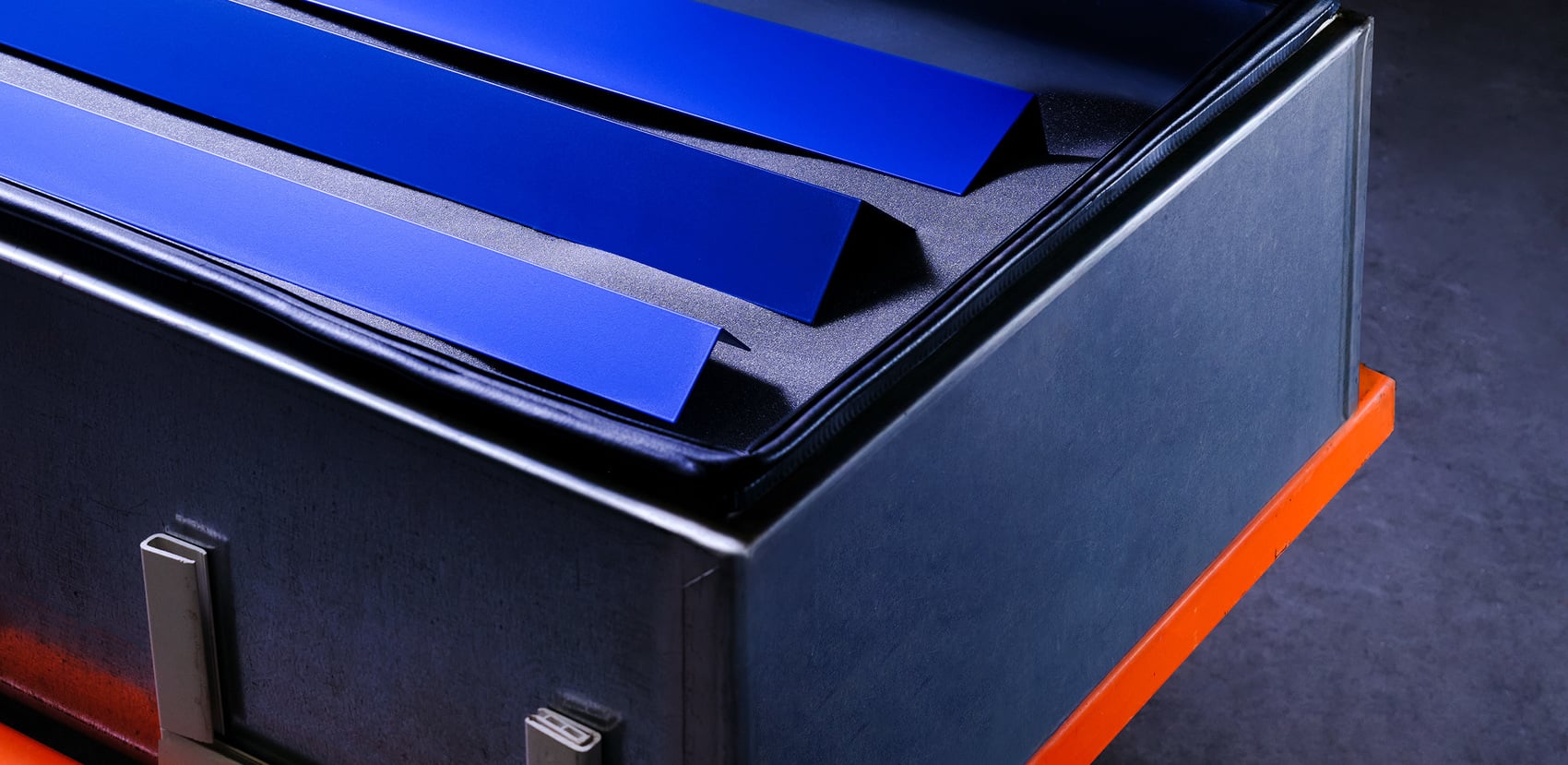

Quality: The large quantity of items ensures constant capacity – and with it the enormous range of colours, right down to the coating of individual frame parts and handles. The consistently comprehensive paint application fulfils the demanding Qualicoat Seaside standard. The facings are packaged up with due care for just-in-time delivery to other plants (photo right).

Glass production

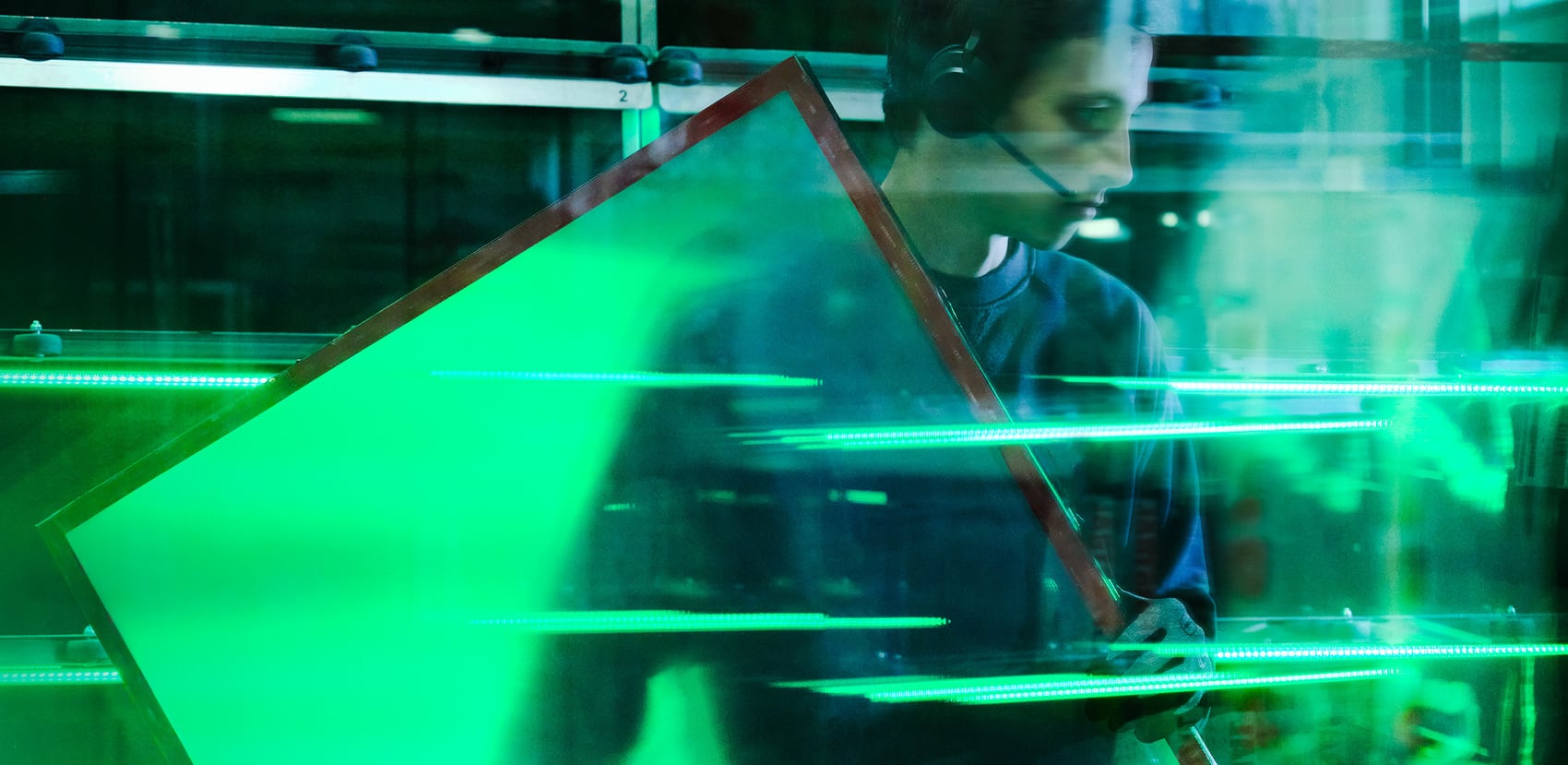

Quality: There are few people in the Finstral insulating glass production facilities; given the large volumes, almost every production step is suitable for automation instead – for greater efficiency and process consistency. Nonetheless, at the end of the process it is not just random samples that are carefully inspected according to RAL and CEKAL guidelines, but every single piece of insulating glass (photo left, here in Oppeano, Italy). A laser scanner conducts an initial check before experienced employees scrutinise the glass by sight.

Quantity: Finstral manufactures insulating glass at three sites – a total of around 11,500 pieces per week, which are cut out of enormous float glass panes (6 x 3.21 metres) in various thicknesses and variations, in a digitally optimised process that keeps offcuts to a minimum. Each pane is seamed, printed with enamel paint if required, or toughened in the oven. The fully automatic central buffer store (photo above) arranges the interim storage and release of an average of 800 panes, ensuring that the production line always puts the right panes together for double or triple glazing.

Window assembly

Quality loves quantity: The Finstral window assembly facility (here: Oppeano, Italy) is where it all comes together – uPVC rods, aluminium and wooden facing, insulating glass. Numerous machines, some of them highly specialised and developed specifically for the plant, cut and mill profiles, introduce steel reinforcement and screw in fittings, weld the corners and remove the residue or “weld beads” (photo left). This makes processes faster and more efficient. And a high standard of fittings comes as default: each window has at least four security locking parts and one sash lifter. Once the window frame is complete, the glass is glued in rather than tapped in, which has numerous benefits. For instance, the angle of the window remains consistently stable, making it more reliable to operate and easier to maintain.

Finstral manufactures around 650,000 window units per year. Each is individual, each a one-off – chosen from over 41 billion possible combinations in the Finstral range. This enormous overall volume both facilitates and requires automation; and it is the machines under the guidance of the production line employees and production technicians that guarantee this huge variety in reliable quality. All this so architects and developers can have genuine freedom of choice in functionality and aesthetics (photo below). With quality you only get from quantity.

Quantity: Since 2019, Finstral has had a powder coating facility for aluminium facings in Borgo Valsugana (Trentino). Around 10,000 rods are processed here every week, delivered from the warehouse in 450 geometric variants – as raw aluminium with at least 50 percent recycled materials. A computer optimises the placement of the hangers and the sequence of process steps, depending on the colour. In total, the Finstral portfolio includes 260 colour variants; 80 to 120 of them are produced in any given week (photo above, here in white).

Quality: The large quantity of items ensures constant capacity – and with it the enormous range of colours, right down to the coating of individual frame parts and handles. The consistently comprehensive paint application fulfils the demanding Qualicoat Seaside standard. The facings are packaged up with due care for just-in-time delivery to other plants (photo right).

Glass production

Quality: There are few people in the Finstral insulating glass production facilities; given the large volumes, almost every production step is suitable for automation instead – for greater efficiency and process consistency. Nonetheless, at the end of the process it is not just random samples that are carefully inspected according to RAL and CEKAL guidelines, but every single piece of insulating glass (photo left, here in Oppeano, Italy). A laser scanner conducts an initial check before experienced employees scrutinise the glass by sight.

Quantity: Finstral manufactures insulating glass at three sites – a total of around 11,500 pieces per week, which are cut out of enormous float glass panes (6 x 3.21 metres) in various thicknesses and variations, in a digitally optimised process that keeps offcuts to a minimum. Each pane is seamed, printed with enamel paint if required, or toughened in the oven. The fully automatic central buffer store (photo above) arranges the interim storage and release of an average of 800 panes, ensuring that the production line always puts the right panes together for double or triple glazing.

Window assembly

Quality loves quantity: The Finstral window assembly facility (here: Oppeano, Italy) is where it all comes together – uPVC rods, aluminium and wooden facing, insulating glass. Numerous machines, some of them highly specialised and developed specifically for the plant, cut and mill profiles, introduce steel reinforcement and screw in fittings, weld the corners and remove the residue or “weld beads” (photo left). This makes processes faster and more efficient. And a high standard of fittings comes as default: each window has at least four security locking parts and one sash lifter. Once the window frame is complete, the glass is glued in rather than tapped in, which has numerous benefits. For instance, the angle of the window remains consistently stable, making it more reliable to operate and easier to maintain.

Finstral manufactures around 650,000 window units per year. Each is individual, each a one-off – chosen from over 41 billion possible combinations in the Finstral range. This enormous overall volume both facilitates and requires automation; and it is the machines under the guidance of the production line employees and production technicians that guarantee this huge variety in reliable quality. All this so architects and developers can have genuine freedom of choice in functionality and aesthetics (photo below). With quality you only get from quantity.

Aluminium powder coating

Aluminium powder coating

Glass production

Glass production

Window assembly

Window assembly

Still want more?

See here for further interesting reading matter.