When does something become waste? When we no longer need it? When it breaks, fades, loses lustre? Or is waste simply an idea – a misunderstanding we need to unlearn? Material doesn’t vanish. It remains. It changes, assumes new forms, tells new stories. A window frame was once bauxite, deep in the ground. A pane of glass starts life as sand in a distant riverbed. uPVC undergoes cycles without losing its resilience. So what if we stopped throwing away and started transforming? Rethinking what we leave behind? Can we build buildings so that they never disappear? So they dissolve, reassemble, carry on? What does self-preserving architecture look like? We went in search of answers, solutions and opportunities. What we found: materials that remain. Circuits that can be closed. And ideas that transform waste into resources.

Text: Julia Christian

Artwork: Kevin Jaeger

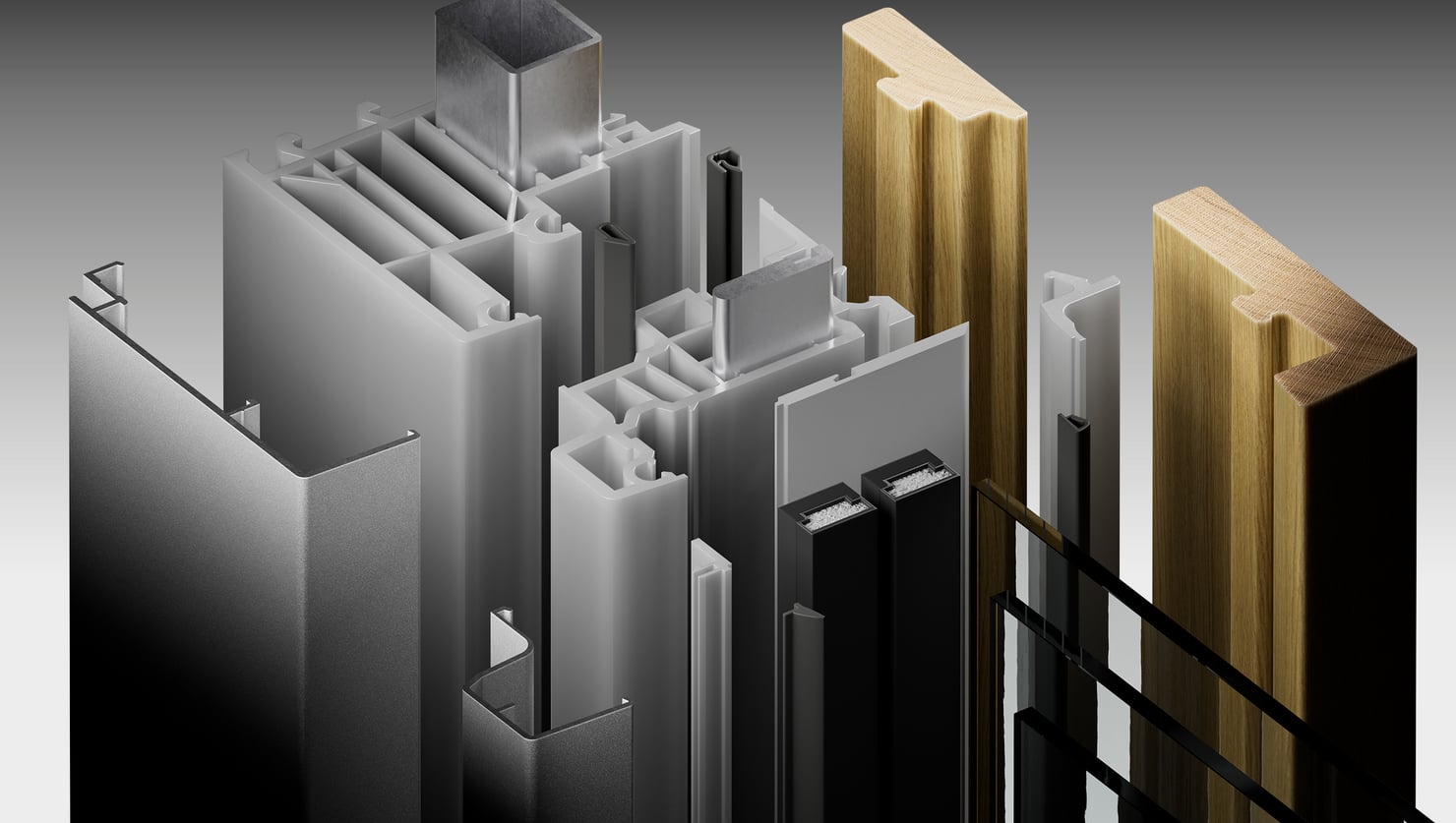

No sustainable building without recycling. The recycling of glass, aluminium and uPVC is a major opportunity for greater sustainability – but is it enough? Because even if these materials are recyclable in principle, the question remains: how often can they be reused, and how much energy does it take? And how much carbon does that involve? Finstral had its own carbon footprint calculated by ClimatePartner – and the results were sobering. While the company is on track for climate neutrality by 2030 for Scope 1 (direct emissions) and Scope 2 (indirect emissions from purchased energy), 95.7% of emissions are Scope 3 (indirect emissions in the value chain) – primarily from the procurement of materials.

This means that the greatest lever for more sustainability isn’t actually within the company’s own production, it’s in the supply chain. So we sat down with the material experts from our major suppliers – Saint-Gobain for glass, Grupa Kęty for aluminium and Orbia Polymer Solutions (Vestolit) for uPVC – and asked them: how circular are their materials? What kind of innovations might improve their reusability? And what has to happen to turn problematic substances into sustainable solutions? Together we analysed the status quo, identified challenges and took a look ahead to the year 2050. Because it will take more than good intentions to make materials recycling the exception rather than the norm. It will take new technologies, political initiative and an industry that questions not just its recycling rate, but its entire climate footprint.