Efficient, environmental and tailor-made.

Building sustainable houses with energy-efficient methods is one of the greatest challenges of the energy transition.

The Belgian company Mobble has developed a forward-looking concept under the same name in cooperation with Ghent University: environmentally responsible wooden houses made up of modular components. Prefabricated in their own workshop, these innovative living units can be placed on open land or inserted in the gaps between buildings.

The Mobble hangs up to ten metres above the ground before the crane sets it down in one of the typically narrow gaps between Belgian terraced houses. In this project in Antwerp, the ground floor is lowered into position, followed by the first floor. Assembly takes just a few hours; the building is fully erected in a single day. This is a major advantage, because the weather can’t impact the delivery or the last construction step – the landing. Production of the small houses is extremely efficient: the company covers the entire fabrication process in its own workshop in Eeklo. Bathroom, kitchen, windows, tiling, floors, even the pipework comes pre-installed, so usually all you need to add once the modules are in place are the stairs. The materials used in the house are sustainable and environmentally responsible: wood predominates, while cellulose and other materials are used for insulation. These building materials can later be disassembled, separated and reused. Modern technologies such as heat pumps and solar panels ensure a sustainable energy balance – and a comfortable indoor climate. After just four months of planning and fabrication, the house is cleared for transportation to the building site.

The Mobble hangs up to ten metres above the ground before the crane sets it down in one of the typically narrow gaps between Belgian terraced houses. In this project in Antwerp, the ground floor is lowered into position, followed by the first floor. Assembly takes just a few hours; the building is fully erected in a single day. This is a major advantage, because the weather can’t impact the delivery or the last construction step – the landing. Production of the small houses is extremely efficient: the company covers the entire fabrication process in its own workshop in Eeklo. Bathroom, kitchen, windows, tiling, floors, even the pipework comes pre-installed, so usually all you need to add once the modules are in place are the stairs. The materials used in the house are sustainable and environmentally responsible: wood predominates, while cellulose and other materials are used for insulation. These building materials can later be disassembled, separated and reused. Modern technologies such as heat pumps and solar panels ensure a sustainable energy balance – and a comfortable indoor climate. After just four months of planning and fabrication, the house is cleared for transportation to the building site.

From a lofty height: a pre-assembled Mobble is delivered on a low loader and positioned on its foundation by crane.

Each unit is customised to the customer’s specific requirements, depending on the plot and orientation. Both planning and construction are modular with the Mobble, so it can respond to life changes. A new addition to the family? A second home office? No problem – adding additional rooms or entire living units is easy. Children moving out? One module of the house can be removed and redeployed elsewhere. The modular construction system means that changes can be planned and executed within just a few weeks.

Just like Finstral, Mobble thinks in modules. So the Belgian company decided to enter into a cooperation with the South Tyrol-based family company. And because Finstral offers everything from a single source – from the development and extrusion of the profiles to the insulating glass manufacturing or aluminium powder coating – it can provide systems in which almost everything can be combined with everything else. The framing material for the exterior of the Mobble is aluminium, available in around 250 different colours; on the inside easy-care uPVC is used, in a choice of seven colours. Both materials are also available in various wood decors.

Just like Finstral, Mobble thinks in modules. So the Belgian company decided to enter into a cooperation with the South Tyrol-based family company. And because Finstral offers everything from a single source – from the development and extrusion of the profiles to the insulating glass manufacturing or aluminium powder coating – it can provide systems in which almost everything can be combined with everything else. The framing material for the exterior of the Mobble is aluminium, available in around 250 different colours; on the inside easy-care uPVC is used, in a choice of seven colours. Both materials are also available in various wood decors.

A hovering wooden house: at Mobble, an everyday sight.

With aluminium on the exterior and uPVC on the interior: these unusually narrow frames from Finstral are long-lasting, robust and available in many different colours.

Product of a modular construction method: a wooden house perfectly tailored to the present living situation of its occupants and adaptable at any time.

Both Mobble and Finstral apply modular concepts that set standards for a more efficient future in the construction sector.

As narrow as it gets: The wooden-frame construction modules fit into even the smallest gap.

But it wasn’t just the consistently modular range that won Mobble over, it was also the sustainable orientation of Finstral – from the use of 100% green electricity in all its 14 plants to the concept of waste-free production, under which offcuts, shavings and residual materials are collected, processed and reused directly wherever possible. And Finstral’s approach to the construction of its elements also corresponds with the Mobble philosophy. Both companies aim for products with optimal functionality, impressive aesthetics, high durability and separability of all materials into pure components after usage – setting standards for a more efficient future in the construction sector.

Project profile:

Property: Slide-in buildings

Construction task: Fitting of window

Architects: on project basis

Year of construction: since 2021

Total area: 100-120 m² (varies by project)

Locality: Belgium

Finstral elements:

Project profile:

Property: Slide-in buildings

Construction task: Fitting of window

Architects: on project basis

Year of construction: since 2021

Total area: 100-120 m² (varies by project)

Locality: Belgium

Finstral elements:

- Window FIN-Window Classic-line 77+8 Aluminium-uPVC

- Lift-and-slide door FIN-Slide Step-line 144 Aluminium-uPVC

- Door FIN-Door Step – Step Frame uPVC-uPVC

Eco-logical! All the materials in the façade, windows and door are in line with sustainability criteria.

The building is slotted in position on the same day.

The entire production process takes place in Mobble's own workshop.

The materials score with their optimum functional performance, convincing aesthetics and high durability.

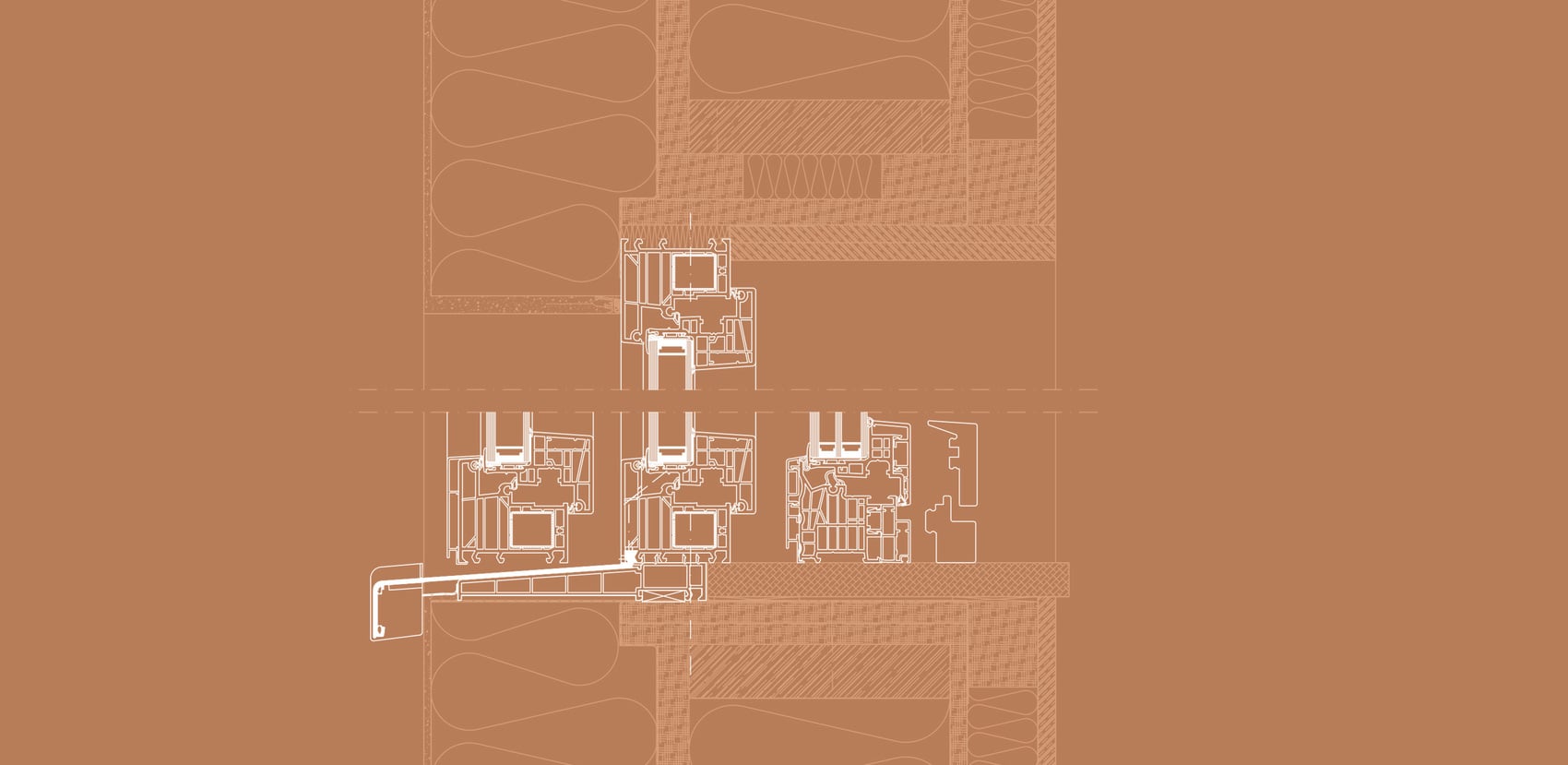

Building connection

If you want to prevent serial construction looking too samey, you need modular solutions with uniform interfaces that allow for variations. That is precisely the strength of the Finstral window range that Mobble buildings use. The building connection of the windows in the industrially produced wall elements for the timber-frame construction is always the same, while the configuration of the elements varies with each project: the frames could be uPVC, uPVC-aluminium or aluminium-wood, while the functionality of the windows could extend to casement doors or window sashes with in-built shading systems. But even with this wide variety of windows they can always be properly installed in the reveal, because the interface of the building connection is always identical.

If you want to prevent serial construction looking too samey, you need modular solutions with uniform interfaces that allow for variations. That is precisely the strength of the Finstral window range that Mobble buildings use. The building connection of the windows in the industrially produced wall elements for the timber-frame construction is always the same, while the configuration of the elements varies with each project: the frames could be uPVC, uPVC-aluminium or aluminium-wood, while the functionality of the windows could extend to casement doors or window sashes with in-built shading systems. But even with this wide variety of windows they can always be properly installed in the reveal, because the interface of the building connection is always identical.

Still want more?

See here for further interesting reading matter.