Always functional.

Always aesthetic.

Always aesthetic.

The founders of Finstral recount in an interview the 50-year success story of their family business in South Tyrol.

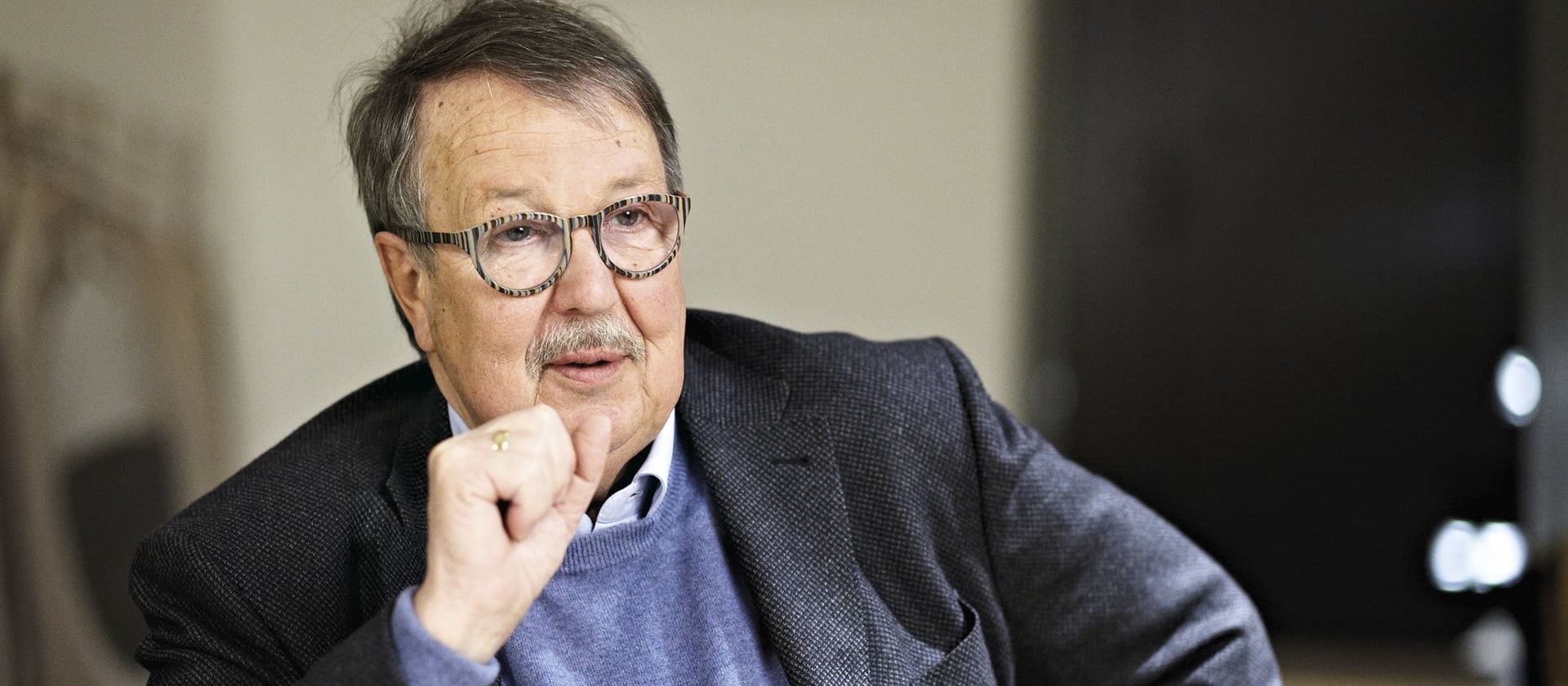

Today we are drawing back the curtains, because we want to know: whose heads are behind them? Six members of the South Tyrolean Oberrauch family work in management positions in the family business. We spoke to three of them: Hans Oberrauch (77), who founded Finstral in 1969 with his partner Max Lintner and who continues to influence the development of new products. Luis Oberrauch (62), who was appointed by his brother Hans in 1976 and is in charge of the Italian division and sales. And finally, Joachim Oberrauch (42), who has followed his father Hans into management and is responsible for the German division and marketing.

Interview: Barbara Teichelmann, Stefan Sippell

HO: Hans Oberrauch LO: Luis Oberrauch JO: Joachim Oberrauch

Two generations of the Oberrauch family at one table. We meet at the Finstral headquarters in Unterinn, a small town, practically a village, above Bozen. The windows in the meeting room are impressively large: through them can be seen the rocky Schlern massif glowing magnificently red in the evening sun. The mood is relaxed, all three seem to be looking forward to the interview… and, at the same time, to the answers that son and brother, nephew, father and uncle will give. As we speak, it gets darker and darker, until finally the glass seems to lose its transparency and turns into a mirror.

How it all began, or: “Functionality and aesthetics”

Finstral has been successfully making uPVC windows for nearly 50 years now. How did you come up with the name Finstral?HO: As a carpenter, I saw how furniture design was developing and I was particularly enthusiastic about Finnish furniture. This extraordinary interplay of functionality and aesthetics had always appealed to me, and I wanted to use this standard as an example. The furniture names often used the term “Finn”. Then came “Strahl”, German for a ray, like that of sunshine through a window… and a window in Italian is “finestra”! The rest was easy.

JO: Really? Finland? I didn’t know that.

LO: Interestingly, for a short time, the company’s name was not spelt as it is now, but had a silent “H”. Exactly like “Strahl”. Perhaps for one, maybe two years.

HO: Not even that. Less, in fact. Just one year.

And why windows?HO: We were carpenters working in the building trade and above all in furniture: a carpentry shop with seven employees. We also made windows back then, but out of wood and only in modest quantities. In 1968 we first came across uPVC windows…

LO: …through adverts in German magazines. Hoechst [1] had a major publicity drive for a new raw material: impact-resistant hard uPVC [1]. It was ideal for windows. Just as it is today.

If you were previously working a lot with wood, it is not necessarily obvious that you would see the future in uPVC…LO: Confidence in Hoechst was very high at this time. What they did was practically holy writ. That’s why we were sure that uPVC could be used for something big.

HO: Although the first three years were really difficult. At the beginning, we purchased almost all the semi-finished products [2] from Germany, i.e. the profiles [2], fittings and so on. But the Italian lira was losing its value so quickly back then…

LO: You’ve determined a price for a window, then even during production everything was getting more and more expensive for us, so we ended up selling the windows at no profit, even at a loss.

HO: In 1972 we decided to develop our own systems and to get an Italian company to extrude the profiles…

JO: …until 1980, when we also took over this aspect of production.

HO: And all of a sudden we started making money because we weren’t so dependent on imports from Germany any more.

LO: Further success came with the involvement of the first German dealer group in the mid-1970s. We had come to their attention through Finstral’s advertising in local newspapers.

HO: In Germany, too, dealers had seen that uPVC was the coming material. Having already done good business with Italian manufacturers of aluminium windows, they naturally assumed that the same was possible with uPVC. And that’s how it was. This involvement brought us growth and happy times.

Mr Oberrauch, was it in these years that you persuaded your younger brother Luis to join Finstral?HO: Exactly. He half came in, and was half dragged in (laughs).

LO: You need people who will get involved. There was a great deal to do at the time.

HO: And the whole venture was a family issue. Even those who were not actively involved at the time had a positive impact.

Corporate philosophy, or: “For the benefit of the customer”

Does Finstral have a corporate philosophy? You talked about functionality and aesthetics…LO: We could describe that as a product philosophy. But a corporate philosophy...

HO: I’ve always been concerned about the benefit to the customer. This attitude could be described as a philosophy. In the world of furniture, of course, it was more a question of design. Design is also important in windows, but it is above all about their functionality. They also have to withstand the weather, making the demands much greater. To this day I still think of how to improve a thing for the benefit of the customer – obviously so that you can sell it, too. Of course.

LO: And it’s also important to us that what we do, we do right: that we do things right in the customer’s interest. That customers get what they expect from us – and rightly so.

HO: In other words, that we always remain credible. And not talking big and then not keeping our promises.

LO: This was probably why we have taken the entire value chain into our own hands over the years – from the processing of uPVC granulate and the production of insulation glass right through to mounting. No one does that except us. But, if everything comes from a single source, the responsibility too is ours. This is both an opportunity and a commitment.

JO: Everything from a single source and so many things from ourselves as the source… this could also be described as a philosophy that runs through the company. For example, we want Finstral to offer career opportunities to people here in the region.

LO: There are in fact many examples of employees who started doing simple tasks in the company and are now important executives.

Family business, or: “Because it’s in our blood”

It means you feel a duty to your homeland. The company is still headquartered at Unterinn on the Ritten mountain.HO: That’s very important for us.

LO: At the same time, we were among the first South Tyrolean companies to expand geographically [3] and then go abroad.

But your heart is still here, where the Finstral headquarters are located?JO: That is true, not just for me, but for our employees too. It’s also because we want to retain the character of a family business.

What is so important to you about that?LO: That we can transfer the structure and culture of a functioning family to the whole company. We have flat hierarchies, make quick decisions, work together in an uncomplicated way and are all deeply involved. Not because this is considered a modern management style but because at Finstral it is, so to speak, in our blood.

Does this mean you treat your relatives in the company no differently from the rest of your employees?JO: If anything, a bit more strictly (laughs). No, we don’t make any difference.

LO: I have recently been amazed to discover how many people have been with us for over 20 or even 30 years. This certainly also reflects how we treat each other in a decent, cooperative, respectful and orderly manner. Tough but factual confrontations are, of course, a part of all that.

JO: We always try to think in a very solution-oriented way. And to discuss matters in the same way.

UPVC, or: “It is the ideal material for a window”

You have indicated how you became aware of uPVC as a material in 1968. What is it that you find so fascinating?HO: Impact-resistant uPVC is a product that effectively delivers what it promises, be it in terms of weather resistance or functionality. We have always been interested in the aesthetic side too – and uPVC lets you make beautiful windows. Then there are factors like its strength when screwing or welding, or the sealing and insulation of the windows. There are so many positive aspects.

LO: It is the ideal material for a window.

HO: Only our emotional response prejudices us against uPVC. There are people who emotionally prefer wood and those who prefer aluminium. There are some too whose enthusiasm is for steel. These are the main materials used in window construction. If you absolutely want wood, you want wood… you can’t do much about it. But as regards functionality, durability and lasting value, we are convinced that we have not over-promised. UPVC [4] is a plausible, sustainable product.

JO: That’s why we are also convinced that, even when using other materials, there always has to be uPVC in the core.

Interview: Barbara Teichelmann, Stefan Sippell

HO: Hans Oberrauch LO: Luis Oberrauch JO: Joachim Oberrauch

Two generations of the Oberrauch family at one table. We meet at the Finstral headquarters in Unterinn, a small town, practically a village, above Bozen. The windows in the meeting room are impressively large: through them can be seen the rocky Schlern massif glowing magnificently red in the evening sun. The mood is relaxed, all three seem to be looking forward to the interview… and, at the same time, to the answers that son and brother, nephew, father and uncle will give. As we speak, it gets darker and darker, until finally the glass seems to lose its transparency and turns into a mirror.

How it all began, or: “Functionality and aesthetics”

Finstral has been successfully making uPVC windows for nearly 50 years now. How did you come up with the name Finstral?HO: As a carpenter, I saw how furniture design was developing and I was particularly enthusiastic about Finnish furniture. This extraordinary interplay of functionality and aesthetics had always appealed to me, and I wanted to use this standard as an example. The furniture names often used the term “Finn”. Then came “Strahl”, German for a ray, like that of sunshine through a window… and a window in Italian is “finestra”! The rest was easy.

JO: Really? Finland? I didn’t know that.

LO: Interestingly, for a short time, the company’s name was not spelt as it is now, but had a silent “H”. Exactly like “Strahl”. Perhaps for one, maybe two years.

HO: Not even that. Less, in fact. Just one year.

And why windows?HO: We were carpenters working in the building trade and above all in furniture: a carpentry shop with seven employees. We also made windows back then, but out of wood and only in modest quantities. In 1968 we first came across uPVC windows…

LO: …through adverts in German magazines. Hoechst [1] had a major publicity drive for a new raw material: impact-resistant hard uPVC [1]. It was ideal for windows. Just as it is today.

If you were previously working a lot with wood, it is not necessarily obvious that you would see the future in uPVC…LO: Confidence in Hoechst was very high at this time. What they did was practically holy writ. That’s why we were sure that uPVC could be used for something big.

HO: Although the first three years were really difficult. At the beginning, we purchased almost all the semi-finished products [2] from Germany, i.e. the profiles [2], fittings and so on. But the Italian lira was losing its value so quickly back then…

LO: You’ve determined a price for a window, then even during production everything was getting more and more expensive for us, so we ended up selling the windows at no profit, even at a loss.

HO: In 1972 we decided to develop our own systems and to get an Italian company to extrude the profiles…

JO: …until 1980, when we also took over this aspect of production.

HO: And all of a sudden we started making money because we weren’t so dependent on imports from Germany any more.

LO: Further success came with the involvement of the first German dealer group in the mid-1970s. We had come to their attention through Finstral’s advertising in local newspapers.

HO: In Germany, too, dealers had seen that uPVC was the coming material. Having already done good business with Italian manufacturers of aluminium windows, they naturally assumed that the same was possible with uPVC. And that’s how it was. This involvement brought us growth and happy times.

Mr Oberrauch, was it in these years that you persuaded your younger brother Luis to join Finstral?HO: Exactly. He half came in, and was half dragged in (laughs).

LO: You need people who will get involved. There was a great deal to do at the time.

HO: And the whole venture was a family issue. Even those who were not actively involved at the time had a positive impact.

Corporate philosophy, or: “For the benefit of the customer”

Does Finstral have a corporate philosophy? You talked about functionality and aesthetics…LO: We could describe that as a product philosophy. But a corporate philosophy...

HO: I’ve always been concerned about the benefit to the customer. This attitude could be described as a philosophy. In the world of furniture, of course, it was more a question of design. Design is also important in windows, but it is above all about their functionality. They also have to withstand the weather, making the demands much greater. To this day I still think of how to improve a thing for the benefit of the customer – obviously so that you can sell it, too. Of course.

LO: And it’s also important to us that what we do, we do right: that we do things right in the customer’s interest. That customers get what they expect from us – and rightly so.

HO: In other words, that we always remain credible. And not talking big and then not keeping our promises.

LO: This was probably why we have taken the entire value chain into our own hands over the years – from the processing of uPVC granulate and the production of insulation glass right through to mounting. No one does that except us. But, if everything comes from a single source, the responsibility too is ours. This is both an opportunity and a commitment.

JO: Everything from a single source and so many things from ourselves as the source… this could also be described as a philosophy that runs through the company. For example, we want Finstral to offer career opportunities to people here in the region.

LO: There are in fact many examples of employees who started doing simple tasks in the company and are now important executives.

Family business, or: “Because it’s in our blood”

It means you feel a duty to your homeland. The company is still headquartered at Unterinn on the Ritten mountain.HO: That’s very important for us.

LO: At the same time, we were among the first South Tyrolean companies to expand geographically [3] and then go abroad.

But your heart is still here, where the Finstral headquarters are located?JO: That is true, not just for me, but for our employees too. It’s also because we want to retain the character of a family business.

What is so important to you about that?LO: That we can transfer the structure and culture of a functioning family to the whole company. We have flat hierarchies, make quick decisions, work together in an uncomplicated way and are all deeply involved. Not because this is considered a modern management style but because at Finstral it is, so to speak, in our blood.

Does this mean you treat your relatives in the company no differently from the rest of your employees?JO: If anything, a bit more strictly (laughs). No, we don’t make any difference.

LO: I have recently been amazed to discover how many people have been with us for over 20 or even 30 years. This certainly also reflects how we treat each other in a decent, cooperative, respectful and orderly manner. Tough but factual confrontations are, of course, a part of all that.

JO: We always try to think in a very solution-oriented way. And to discuss matters in the same way.

UPVC, or: “It is the ideal material for a window”

You have indicated how you became aware of uPVC as a material in 1968. What is it that you find so fascinating?HO: Impact-resistant uPVC is a product that effectively delivers what it promises, be it in terms of weather resistance or functionality. We have always been interested in the aesthetic side too – and uPVC lets you make beautiful windows. Then there are factors like its strength when screwing or welding, or the sealing and insulation of the windows. There are so many positive aspects.

LO: It is the ideal material for a window.

HO: Only our emotional response prejudices us against uPVC. There are people who emotionally prefer wood and those who prefer aluminium. There are some too whose enthusiasm is for steel. These are the main materials used in window construction. If you absolutely want wood, you want wood… you can’t do much about it. But as regards functionality, durability and lasting value, we are convinced that we have not over-promised. UPVC [4] is a plausible, sustainable product.

JO: That’s why we are also convinced that, even when using other materials, there always has to be uPVC in the core.

Joachim Oberrauch

A Finstral management meeting in the ultra-modern conservatory production hall. From left to right: Luis Oberrauch (vice-chairman of the board of directors), Joachim Oberrauch (member of the board of directors), Hans Oberrauch (chairman of the board of directors).

Finstral developments, or: “You need to be a little bit stubborn.”

Finstral is committed to continually moving the industry forwards with new developments. What have been the most important innovations in the company’s history?HO: The 200 profile system, which we launched in 1979. That is still today the foundation for the best.

LO: And the surfaces. Our embossed surfaces [5] are a Finstral trademark. In the 1980s wood texture surfaces were in great demand. At the beginning we employed a system under licence that used wood foil. But then we began experimenting ourselves and developed new methods. We just worked directly on the uPVC without using foil – and the result was a great surface. It was something completely new, nobody else did it like that, and the market took it up very quickly and enthusiastically.

HO: Good dealers and retailers are always looking for something to differentiate themselves, to make them stand out in the eyes of their customers. And it isn’t just a matter of price.

JO: Our unique selling point for surfaces enables us to be a success on the market.

HO: We have always tried to develop techniques so that you can make more of the whole. This can only be done by trying and trying and trying… until it finally works. You need to be a little bit stubborn. It means a lot of work, but it has always opened up new avenues for us. Fortunately, our employees are always interested in new things.

Back to Finstral’s big innovations: the 200 system, then the surfaces – and what else?JO: In 2001, we started to bond our windows [6] rather than using setting blocks. This way we could make profiles with an extremely slender appearance…

HO: …and operating the window was made easier. Opening, closing: everything feels of much better quality. And will function over a long period.

LO: And then there is of course our FIN-Project window system! [7] This saw the introduction of our modular window frame design. That is, we divide each frame into three levels: outer level, core, and inner level. The core has the functions of insulating, sealing, containing the fittings and the insulation glass. The outer and inner layers are what make the appearance and can be in different materials and colours, for example in different aluminium variants. This allows you to combine almost any window you want.

JO: Nor should we forget: with our new glass hardening furnace and the glass processing facilities that we installed at our Scurelle plant in 2014, there are completely new possibilities to include the glass in developments right from the start. The results are reflected in our Cristal design line, which offers a new look for Finstral windows: the glass completely covers the frame.

LO: It looks really modern and light. And it has all the functions that are important for us and our customers.

What for you has driven your sales?JO: Cultivating the market. In the mid-1980s we started to enter new markets: after Germany came France, the Netherlands, Spain and others.

LO: We were not actually best placed for going into these markets, as we did not have much experience of them. In terms of language and culture, just going to France was an adventure. But it went well and, in retrospect, you can say that those were good times.

HO: Happy travels. Happy travels (laughs).

Customer requirements, or: “It must look good, but it also has to last for 40 years”

How have customer window requirements changed over the years?LO: Our customers want more choice… in terms of design, of equipment… in addition, certain needs have changed, so today the demand for thermal insulation is different. Security is also a major issue today. And the idea of aesthetics has changed, it’s changing enormously right now.

In what way?JO: Slimmer and slimmer frames, less and less visible, preferably just walls and glass - we clearly notice that as an architectural trend at the moment. Slender, delicate and yet with perfect technology. So functionality cannot be ignored.

Is that something that bothers you as a window maker… that customers and architects are demanding less and less frame for their windows?LO: Of course, there has to be a frame because of the functionality. It must look good, but it also has to last for 40 years. We feel a commitment to the customer in this respect.

JO: Security is another point.

LO: Safety combined with good design.

HO: And good insulation.

LO: There was an attempted break-in at the home of one of our employees, but fortunately the modern Finstral window stopped the burglar from getting in. It is an ever-present, burglary and the feeling of worry. At the same time, however, customers do not want to miss out on good design. This is an important aspect for us as window manufacturers.

HO: Mounting techniques have also gained in importance. Although it was not seen as such in the past, the installation is really very important indeed. You have to be able to master it.

JO: That’s why we have made mounting [8] into a major topic in recent years. Because that is where we are in contact with the customer, that is the last phase in the chain, only then will our work be completed. In addition to perfect installation, this also includes simple things like cleaning up the customer’s premises after the work is done. That is why we have introduced consistent quality assurance as regards mounting operations for direct sales and for Finstral dealers.

Finstral is committed to continually moving the industry forwards with new developments. What have been the most important innovations in the company’s history?HO: The 200 profile system, which we launched in 1979. That is still today the foundation for the best.

LO: And the surfaces. Our embossed surfaces [5] are a Finstral trademark. In the 1980s wood texture surfaces were in great demand. At the beginning we employed a system under licence that used wood foil. But then we began experimenting ourselves and developed new methods. We just worked directly on the uPVC without using foil – and the result was a great surface. It was something completely new, nobody else did it like that, and the market took it up very quickly and enthusiastically.

HO: Good dealers and retailers are always looking for something to differentiate themselves, to make them stand out in the eyes of their customers. And it isn’t just a matter of price.

JO: Our unique selling point for surfaces enables us to be a success on the market.

HO: We have always tried to develop techniques so that you can make more of the whole. This can only be done by trying and trying and trying… until it finally works. You need to be a little bit stubborn. It means a lot of work, but it has always opened up new avenues for us. Fortunately, our employees are always interested in new things.

Back to Finstral’s big innovations: the 200 system, then the surfaces – and what else?JO: In 2001, we started to bond our windows [6] rather than using setting blocks. This way we could make profiles with an extremely slender appearance…

HO: …and operating the window was made easier. Opening, closing: everything feels of much better quality. And will function over a long period.

LO: And then there is of course our FIN-Project window system! [7] This saw the introduction of our modular window frame design. That is, we divide each frame into three levels: outer level, core, and inner level. The core has the functions of insulating, sealing, containing the fittings and the insulation glass. The outer and inner layers are what make the appearance and can be in different materials and colours, for example in different aluminium variants. This allows you to combine almost any window you want.

JO: Nor should we forget: with our new glass hardening furnace and the glass processing facilities that we installed at our Scurelle plant in 2014, there are completely new possibilities to include the glass in developments right from the start. The results are reflected in our Cristal design line, which offers a new look for Finstral windows: the glass completely covers the frame.

LO: It looks really modern and light. And it has all the functions that are important for us and our customers.

What for you has driven your sales?JO: Cultivating the market. In the mid-1980s we started to enter new markets: after Germany came France, the Netherlands, Spain and others.

LO: We were not actually best placed for going into these markets, as we did not have much experience of them. In terms of language and culture, just going to France was an adventure. But it went well and, in retrospect, you can say that those were good times.

HO: Happy travels. Happy travels (laughs).

Customer requirements, or: “It must look good, but it also has to last for 40 years”

How have customer window requirements changed over the years?LO: Our customers want more choice… in terms of design, of equipment… in addition, certain needs have changed, so today the demand for thermal insulation is different. Security is also a major issue today. And the idea of aesthetics has changed, it’s changing enormously right now.

In what way?JO: Slimmer and slimmer frames, less and less visible, preferably just walls and glass - we clearly notice that as an architectural trend at the moment. Slender, delicate and yet with perfect technology. So functionality cannot be ignored.

Is that something that bothers you as a window maker… that customers and architects are demanding less and less frame for their windows?LO: Of course, there has to be a frame because of the functionality. It must look good, but it also has to last for 40 years. We feel a commitment to the customer in this respect.

JO: Security is another point.

LO: Safety combined with good design.

HO: And good insulation.

LO: There was an attempted break-in at the home of one of our employees, but fortunately the modern Finstral window stopped the burglar from getting in. It is an ever-present, burglary and the feeling of worry. At the same time, however, customers do not want to miss out on good design. This is an important aspect for us as window manufacturers.

HO: Mounting techniques have also gained in importance. Although it was not seen as such in the past, the installation is really very important indeed. You have to be able to master it.

JO: That’s why we have made mounting [8] into a major topic in recent years. Because that is where we are in contact with the customer, that is the last phase in the chain, only then will our work be completed. In addition to perfect installation, this also includes simple things like cleaning up the customer’s premises after the work is done. That is why we have introduced consistent quality assurance as regards mounting operations for direct sales and for Finstral dealers.

“And it’s also important to us that what we do, we do right. That we do things right in the customer’s interest. That customers get what they expect from us – and rightly so.”

Tips for home builders, or: “Finstral, Finstral, Finstral”

Have you got three quick tips for someone building a house and making the decision: “Which are the best windows for me?”LO: The three most important tips for a property are: location, location, location. The three best tips for good windows are then: Finstral, Finstral, Finstral (laughs).

HO: I would say that a uPVC-aluminium combination is a very good choice for a house builder. Because it meets every requirement.

JO: Windows that are not too small, that are big enough…

HO: And narrow profiles. All these have a positive effect on the feeling of comfort. Wide-framed windows look heavy and make the room seem heavy. When they are slim, the room becomes lighter.

LO: But I also believe that window surfaces should not be overdone. Glass is a fascinating material; there is, in principle, an enormous range of things that glass can do. But it also needs walls and materials that can store heat.

The view out of the window, or: “Where you feel free”

How important for you is the view through a window? Does this influence you, even in your work?HO: Whenever I stay in a hotel, I always first go to the window. And I am delighted when I see a beautiful landscape or an atmospheric cityscape. If I have to look down at a dark or untidy courtyard, I don’t feel so good any more. I can draw the curtains, but the depressing impression remains.

LO: I think that a good environment helps you to work. Somewhere where you can really see, where you feel free.

HO: Nor is communication through the window unimportant, either. It was once even more popular than it is today.

Do you also get boys sneaking in through their girlfriends’ windows in South Tyrol, like in Bavaria? Lads who would prop a ladder against the window of their sweethearts and climb up…LO: Not any more. Today they all go straight in through the door.

JO: Or via Facebook (laughs).

A passion for making windows, or: “I always look around me”

What is it like when you’re out and about walking through a city – do you look at the windows? Or can you ignore them?JO: Often. A lot. Actually, I always look around me.

LO: My wife says that I always have my head in the air.

HO: That’s also what others say about me. But it’s dangerous from a road safety perspective (laughs).

LO: If I am in a big city… with old buildings and thousands of windows, I ask myself, who once made all of these? You observe and you look and learn: the windows in a certain country look like this and are installed like that. Our job is not only to run the company, but also to understand something about the whole matter itself. It’s something that has never changed: we are simply interested in and passionate about windows.

Would you say you have an emotional relationship with windows?JO: I think so, yes. If you only see a window objectively and merely from the technical side, you cannot maintain your motivation for such a product. You need emotionality to stay passionate about windows as a product for so long.

HO: I didn’t want to have anything to do with windows at first. I just wanted to make furniture, as a carpenter. I was also quite heavily involved in the initial business. At first I saw windows as boring, but things turned out differently. Windows are an unending source of interest.

[1] Hoechst, hard UPVC

Hoechst AG was one of Germany’s largest chemical and pharmaceutical companies. In 1958 it launched Hostalit Z, a high-impact hard uPVC for the construction industry, which became very important for window production in the 1960s. To this day hard uPVC forms the basis for every uPVC window; and to this day there are numerous manufacturers of this raw material. By the way, the first uPVC windows were manufactured by Dynamit-Nobel AG in 1954.

[2] Semi-finished products / profiles

Semi-finished products is the umbrella term used for prefabricated items. In the case of a uPVC window, this can for example mean the profiles. A window frame is composed of profiles that are pressed (extruded) in the form of a long strand. But not every profile is the same: depending on the manufacturer, the cross-section will have a very specific structure – it is the “fingerprint” of each window system manufacturer.

[3] Production facilities

Finstral has 14 production plants in Italy and Germany. Its windows are distributed by over 1,000 dealers in 14 different European countries. In addition, Finstral has its own sales offices in Spain, France, Switzerland, Germany and the Netherlands.

[4] Plastic / uPVC

Finstral uses impact-resistant hard uPVC, an extremely durable and stable form of plastic. UPVC can be processed into almost any shape, it is one of the best insulation materials and is 100 percent recyclable. UPVC from Finstral windows is reprocessed at the company’s own recycling plant into pure granulate and used in the production of new profiles.

[5] Surfaces

The embossed uPVC profile surfaces are available from Finstral in a variety of designs: with a painted wood appearance in white, antique white or pearl white. Or as a satin-finished uPVC surface with a modern, silk-matt look in white, silk grey or grey. The embossing process makes the surface harder, with fewer micropores. This makes it more scratch-resistant and easier to clean than smooth uPVC window frames.

[6] Bonding instead of setting blocks

Bonding is a technique for anchoring the glass pane in the frame. Traditionally, setting blocks are used, which means that the glass pane is wedged into the frame at intervals using plastic blocks to ensure angular stability. With bonding, on the other hand, the glass is affixed all around to the movable sash frame to form a stable unit. This technique ensures better stability over time with maximum ease of operation.

[7] FIN-Project

FIN-Project is the name of a Finstral window system that features a uPVC core and aluminium glazing. The uPVC profiles in the core guarantee reliable thermal insulation and very good sealing. The weather-resistant, aesthetically pleasing aluminium on the outside and, optionally, on the inside is particularly easy to care for and offers exceptional freedom of design, with all RAL colours available. Real wood can also be used for the interior and – for the first time in window construction – we offer our sustainable material ForRes, a mixture of uPVC and rice husks. Depending on your wishes, different frame shapes can be selected, up to the FIN-Project Nova-line Cristal Twin: the sash frame disappears completely behind the glass on both the interior and the exterior.

[8] Mounting certification

In 2013 Finstral obtained mounting certification from the Institut für Fenstertechnik in Rosenheim (ift). Under this certification, we offer installation planning drawings that have been tested by the ift and continuous training for all employees involved in the mounting process. As part of the quality management process, internal samples are taken with an action plan, while external monitoring is also carried out by the ift. Finstral dealers too are certified according to this system.

Have you got three quick tips for someone building a house and making the decision: “Which are the best windows for me?”LO: The three most important tips for a property are: location, location, location. The three best tips for good windows are then: Finstral, Finstral, Finstral (laughs).

HO: I would say that a uPVC-aluminium combination is a very good choice for a house builder. Because it meets every requirement.

JO: Windows that are not too small, that are big enough…

HO: And narrow profiles. All these have a positive effect on the feeling of comfort. Wide-framed windows look heavy and make the room seem heavy. When they are slim, the room becomes lighter.

LO: But I also believe that window surfaces should not be overdone. Glass is a fascinating material; there is, in principle, an enormous range of things that glass can do. But it also needs walls and materials that can store heat.

The view out of the window, or: “Where you feel free”

How important for you is the view through a window? Does this influence you, even in your work?HO: Whenever I stay in a hotel, I always first go to the window. And I am delighted when I see a beautiful landscape or an atmospheric cityscape. If I have to look down at a dark or untidy courtyard, I don’t feel so good any more. I can draw the curtains, but the depressing impression remains.

LO: I think that a good environment helps you to work. Somewhere where you can really see, where you feel free.

HO: Nor is communication through the window unimportant, either. It was once even more popular than it is today.

Do you also get boys sneaking in through their girlfriends’ windows in South Tyrol, like in Bavaria? Lads who would prop a ladder against the window of their sweethearts and climb up…LO: Not any more. Today they all go straight in through the door.

JO: Or via Facebook (laughs).

A passion for making windows, or: “I always look around me”

What is it like when you’re out and about walking through a city – do you look at the windows? Or can you ignore them?JO: Often. A lot. Actually, I always look around me.

LO: My wife says that I always have my head in the air.

HO: That’s also what others say about me. But it’s dangerous from a road safety perspective (laughs).

LO: If I am in a big city… with old buildings and thousands of windows, I ask myself, who once made all of these? You observe and you look and learn: the windows in a certain country look like this and are installed like that. Our job is not only to run the company, but also to understand something about the whole matter itself. It’s something that has never changed: we are simply interested in and passionate about windows.

Would you say you have an emotional relationship with windows?JO: I think so, yes. If you only see a window objectively and merely from the technical side, you cannot maintain your motivation for such a product. You need emotionality to stay passionate about windows as a product for so long.

HO: I didn’t want to have anything to do with windows at first. I just wanted to make furniture, as a carpenter. I was also quite heavily involved in the initial business. At first I saw windows as boring, but things turned out differently. Windows are an unending source of interest.

[1] Hoechst, hard UPVC

Hoechst AG was one of Germany’s largest chemical and pharmaceutical companies. In 1958 it launched Hostalit Z, a high-impact hard uPVC for the construction industry, which became very important for window production in the 1960s. To this day hard uPVC forms the basis for every uPVC window; and to this day there are numerous manufacturers of this raw material. By the way, the first uPVC windows were manufactured by Dynamit-Nobel AG in 1954.

[2] Semi-finished products / profiles

Semi-finished products is the umbrella term used for prefabricated items. In the case of a uPVC window, this can for example mean the profiles. A window frame is composed of profiles that are pressed (extruded) in the form of a long strand. But not every profile is the same: depending on the manufacturer, the cross-section will have a very specific structure – it is the “fingerprint” of each window system manufacturer.

[3] Production facilities

Finstral has 14 production plants in Italy and Germany. Its windows are distributed by over 1,000 dealers in 14 different European countries. In addition, Finstral has its own sales offices in Spain, France, Switzerland, Germany and the Netherlands.

[4] Plastic / uPVC

Finstral uses impact-resistant hard uPVC, an extremely durable and stable form of plastic. UPVC can be processed into almost any shape, it is one of the best insulation materials and is 100 percent recyclable. UPVC from Finstral windows is reprocessed at the company’s own recycling plant into pure granulate and used in the production of new profiles.

[5] Surfaces

The embossed uPVC profile surfaces are available from Finstral in a variety of designs: with a painted wood appearance in white, antique white or pearl white. Or as a satin-finished uPVC surface with a modern, silk-matt look in white, silk grey or grey. The embossing process makes the surface harder, with fewer micropores. This makes it more scratch-resistant and easier to clean than smooth uPVC window frames.

[6] Bonding instead of setting blocks

Bonding is a technique for anchoring the glass pane in the frame. Traditionally, setting blocks are used, which means that the glass pane is wedged into the frame at intervals using plastic blocks to ensure angular stability. With bonding, on the other hand, the glass is affixed all around to the movable sash frame to form a stable unit. This technique ensures better stability over time with maximum ease of operation.

[7] FIN-Project

FIN-Project is the name of a Finstral window system that features a uPVC core and aluminium glazing. The uPVC profiles in the core guarantee reliable thermal insulation and very good sealing. The weather-resistant, aesthetically pleasing aluminium on the outside and, optionally, on the inside is particularly easy to care for and offers exceptional freedom of design, with all RAL colours available. Real wood can also be used for the interior and – for the first time in window construction – we offer our sustainable material ForRes, a mixture of uPVC and rice husks. Depending on your wishes, different frame shapes can be selected, up to the FIN-Project Nova-line Cristal Twin: the sash frame disappears completely behind the glass on both the interior and the exterior.

[8] Mounting certification

In 2013 Finstral obtained mounting certification from the Institut für Fenstertechnik in Rosenheim (ift). Under this certification, we offer installation planning drawings that have been tested by the ift and continuous training for all employees involved in the mounting process. As part of the quality management process, internal samples are taken with an action plan, while external monitoring is also carried out by the ift. Finstral dealers too are certified according to this system.

What a view: opposite the Finstral headquarters in Unterinn on the Ritten (near Bozen), the Schlern massif rises majestically to a height of 2563 metres. It is regarded as one of the most symbolic mountains of the Dolomites – and is thus a landmark for South Tyrol.

Still want more?

See here for further interesting reading matter.